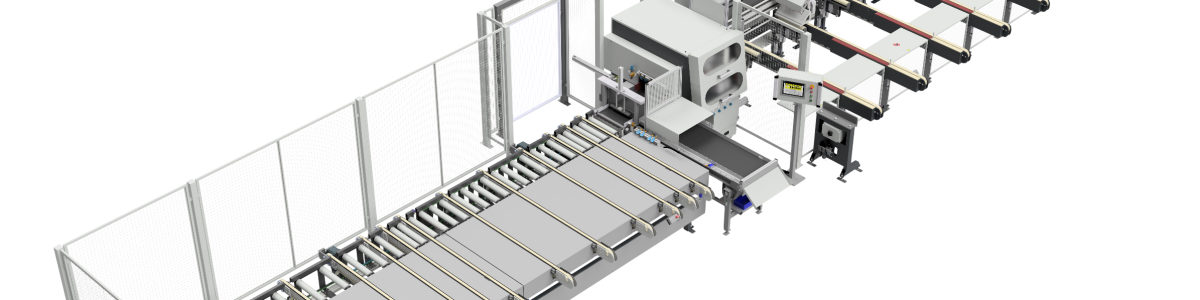

Cutting line with loading magazine and profile disposal for small parts and take-off stations for cut-off lengths up to 7,200 mm or 2 times up to 3,000 mm.

Technical data:

Sawing line for cut-off lengths from 10 to 7200mm

sawing width min. 10mm up to max. 470mm

sawing height min. 10mm up to max. 200mm

remnants from 85mm

Loading magazine:

The loading magazine of the saw unit is synchronously driven by a three-phase motor and a common shaft.

The belts of the loading magazine are 50mm wide and without compartments, therefore no changeover is necessary when changing profiles.

The profiles or the profile layers are fed step by step to the material gripper, the length of the transport stroke depends on the profile or layer width.

Material feed pusher:

The saw line is equipped with an electronically positionable feed system with max. feed length 7300mm with linear motor and magnetic tape.

The repeatability is +/- 0,1mm and the traversing speed is max. 180m/min.

By entering the profile data in the database of the control system, the pusher automatically adjusts to the profile height.

The lower clamping jaws can be moved pneumatically. The upper clamping jaws and the clamping is realized by threaded spindle and servo motor.

In addition, the gripper is mounted floating in the Y-axis to compensate for profile inaccuracies.

Furthermore, the upper clamping jaw can be equipped with interchangeable pressure pieces, if necessary.

Circular sawing machine KS600R:

Radial circular saw machine running over table from back to front, saw blade feed via ball screw and servo motor.

Motor 18,5 KW, direct drive stepless speed control via control. Speed range 2000 to 3300 rpm.

Use of saw blades with diameter up to max. 650mm.

Vertical clamping device left/right of the saw blade, drive via ball screw and servo motor, clamping pressure adjustable via the control.

Horizontal clamping device, pneumatic left/right of the saw blade, presetting to the profile width manually.

Clamping pressure reduction horizontal with 2 pressure regulators.

Cutting gap extension on both sides of the saw blade.

Minimum spraying device with level monitoring and the spraying quantity can be changed via the control and stored in the database according to the profile.

Profile section disposal :

Cuts, remnants and good parts are transported out of the machine frame via a conveyor belt.

Good parts from 10 to 500 mm are pushed onto a cross conveyor belt and transported out of the safety cell.

Good parts from 501mm to 7200mm are transported out of the machine by a driven roller conveyor and out of the safety cell by a belt conveyor.

The sections are lined up at the beginning of the conveyor, either 2 sections from 501 – 3,000mm or one section up to 7200mm can be deposited.

Electrical equipment:

- Control Simatic S 7-300, with touch screen 10″.

- Input of single dimensions with piece counter with target/actual display

- Input of profile or layer heights and widths

- profile database

- Piece counter

- Piece count multiplier for working with profile bundles

- Shutdown in case of excessive cutting pressure

- Network interface with VPN router